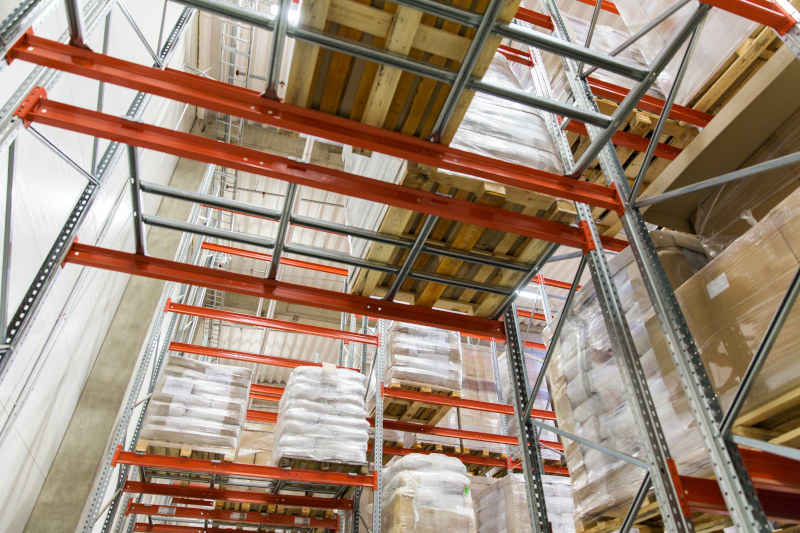

Pallet racking is a versatile storage solution that can be used to maximise the storage space of any warehouse and optimise warehouse operations. However, it is essential that pallet racking systems are correctly installed, and regularly maintained, to avoid a costly pallet racking collapse. Not only can a racking collapse cause thousands of dollars in product and property damage, it can also cause worker injuries.

There are five common pallet racking safety hazards that every warehouse manager should be aware of in order to safeguard from a pallet racking collapse:

- Collision Damage

- Improper Use

- Overhanging Products

- Damaged Beams

- And Incorrectly Installed Racking

1) Collision Damage

Pallet racking systems are made to be durable and withstand the harsh environment of the warehouse. This means that one of the only things in a warehouse that poses a risk of physical damage to a pallet racking system is a forklift collision.

When a forklift collision occurs, damaged frames should be assessed to determine whether the structural integrity of the system has been compromised. Any significantly damaged frames should immediately be repaired or replaced. To ensure that this happens, workers should be trained to report any damage to the racking system as soon as it occurs, including minor impacts.

Training workers to report racking damage is essential, as damage to load bearing columns caused by collisions can contribute to a pallet racking collapse.

Warehouse protection items such as rack bollards, frame end guards, and drive in floor channels can also be used to prevent or minimise the damage caused to pallet racking systems in the event of a forklift collision. Additionally, it is important to consider the specifications of your manual handling equipment when installing pallet racking to ensure that there is sufficient clearance space for easy maneuverability.

2) Improper Use

Using a pallet racking system in a way that it was not designed for is another pallet racking safety hazard. To prevent workers from injury and pallet racking from damage, it is important that anyone operating manual handling equipment has had adequate training in the proper use, and weight limits, of the equipment they will be using.

Additionally, overloading can cause racking to become damaged and is one of the leading causes of pallet racking failure. To help prevent overloading, the weight limits of the pallet racking system, as specified by the manufacturer, should be clearly displayed and adhered to when loading pallets. Workers should also be trained to place loads evenly, as well as to check the maximum weight capacity of a rack before loading new pallets.

3) Overhanging Products

Another common pallet racking safety hazards is overhanging products. Pallets with overhanging products that are being stored on a racking system designed for the pallet size only can cause product damage. It can also become a safety hazard when the length of the overhanging product surpasses the depth of the shelf. This is particularly prevalent in warehouses that purchase used pallet racking, as the racking system is not specifically designed for the product range it is storing.

Commissioning a custom made pallet racking system ensures that the racks are specifically designed to store your product range, allowing the racking manufacturer to take product overhang into account when determining the required shelf width and depth. This ensures that overhanging products will not become a safety hazard.

4) Damaged Beams

Beams are an integral part of any pallet racking system, and when they become damaged it can affect the load capacity of the entire system. Damage to beams is most commonly caused by overloading and collisions. All beams should be regularly inspected for deflection and damage that could indicate a more serious problem.

Any damaged beams should be immediately replaced to prevent racking collapse, potential product damage, and worker injury.

5) Incorrectly Installed Racking

Incorrectly installed pallet racking is another common pallet racking hazard. When pallet racking is installed incorrectly it creates a health and safety issue for anyone working in the warehouse. This hazard can be easily avoided by simply having the racking system installed by pallet racking specialists.

As the racking system is installed, ensure that the racks are properly aligned, flush, and level, and installed as per the specifications provided by the manufacturer.

Book An Inspection

To ensure that your pallet racking system is in good working condition book a pallet racking safety audit with MACRACK today. Our team of racking auditors are highly trained and experienced in auditing all brands of racking. Call us today on 07 3343 9788 to set up an onsite meeting with one of our auditors.