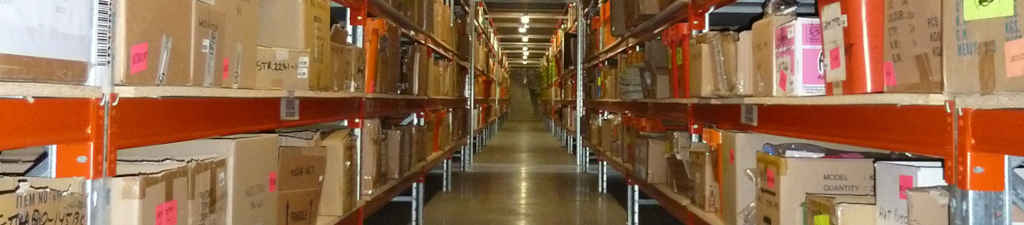

When it comes to warehousing, there is always room for improvement, from increasing storage capacity to maximising efficiency and productivity. From neglected housekeeping to unused space, there are a number of common warehousing mistakes that are costing warehouses tens of thousands of dollars each year in lost revenue.

4 Common Warehousing Mistakes (And How To Avoid Them)

1) Neglecting Housekeeping

In a busy warehouse environment, productivity and efficiency are a top priority and housekeeping is often the last thing on anybody’s mind. However, neglecting housekeeping can cause reduced productivity and create avoidable safety hazards.

Obstructions littered through the aisles such as discarded packaging and shrink wraps, as well as overfilled pallets, pose a health and safety risk and can result in falls, injuries, and damage to dropped products. Additionally, obstructed pathways can slow productivity as forklift drivers and workers will have to navigate through messy aisles.

To avoid unnecessary injuries and losses in productivity, it’s important to allow time for regular cleaning each day to ensure that your warehouse is as organised and safe as possible for maximum productivity.

2) Poor Health & Safety Management

A warehouse is a dangerous working environment that requires constant attention to worker health and safety to reduce the risk of injury. However, it’s easy to make the mistake of overlooking safety when accidents are few and far between.

To avoid preventable accidents and injuries ensure that there is a culture of reporting accidents and near misses in your warehouse. This will enable you to address any safety issues in your warehouse early and prevent potential injuries. Additionally, implement regular safety training to keep safety procedures fresh in the minds of your team.

Not only will this save you money, it will also help to prevent your workers from serious, and even lethal, accidents.

3) Using The Same Racking System For An Evolving Inventory

Another common warehousing mistake that can cost you time and money is using the same type of racking system for a varying range of products. This often occurs when a product range adapts and changes over time, but the racking system is not updated to reflect this. Similarly, buying a second hand racking system for cheap can result in products being stored in unsuitable racking as the racks were not originally designed to store those products.

For example, a warehouse storing bulk amounts of the same product may use a double deep racking system to maximise storage. However, if they added a significant number of SKUs to their inventory without updating or adding to their existing racking, they would face the problem of not having accessibility to each product stored in the racks.

On the other hand, a warehouse that starts with a high number of SKUs, storing one or two pallets of each product at a time, would benefit from a high accessibility product range such as a selective racking system. Yet, if over time they reduced the number of SKUs stored, and instead started storing bulk amounts of each product, a selective racking system would not be as effective as a high density racking system such as drive in pallet racks.

To maximise storage and productivity it is important to reevaluate and update your racking system as your product range evolves. MACRACK offers customisable racking systems, designed for the storage of your products, that can be added to and relocated as your inventory grows and changes.

4) Ignoring Vertical Space

Finally, don’t make the mistake of ignoring the unused vertical space in your warehouse as it can increase storage capacity and boost productivity. If, like many warehouses, there is a large amount of unused vertical space above the racking in your warehouse, you are missing out on an opportunity to improve your warehouse operations.

A warehouse mezzanine floor is a free standing structure that can be built above an existing racking system to create additional floor and storage space. Rather than having to relocate to increase storage capacity, a warehouse mezzanine floor can be used to do this in the space that you are already paying for.

Plus, MACRACK offer multi-level mezzanine floors to double or even triple the floor and storage space in your warehouse without having to renovate or relocate.

Whether you’re looking to update your storage system to fit your growing product range or increase your warehouse storage with a warehouse mezzanine floor, MACRACK has the solution. As Australia’s leading pallet racking manufacturer, providing quality, Australian made racking for over 40 years, MACRACK are the experts when it comes to warehouse storage. Call us today on 100 048 821 a free quote.