Forklifts are used in warehouses and construction to quickly and efficiently shift pallets and bulk materials. Forklifts come in many different shapes, sizes, load capacities, and fuel types. With so many different options available, it can be hard to determine which type of forklift is best for your needs, whether it be loading pallets into a warehouse racking system or transporting building materials across a construction site.

If you’re looking for a reliable material handling solution for your warehouse or construction project, a forklift could be the answer.

Different Types Of Forklifts (And Their Uses)

Counterbalance Forklift

Counterbalance forklifts are the most popular model of forklift suitable for a range of applications. As the name suggests, counterbalance forklifts are built with a set of tynes at the front and a counterweight at the back, which is used to counterbalance heavy loads when help on the tynes.

Available in a wide range of models and fuel types, counterbalance forklifts are suitable for use across a wide range of industries and applications. While able to be used both indoors and outdoors, counterbalance forklifts are typically used indoors in warehouses.

A standard counterbalance forklift is compatible for use with a range of pallet racking systems, including selective pallet racking, push back racking, and pallet flow racking. However, there are a number of different attachments available for counterbalance forklifts to make them compatible for use with more specialised racking systems such as carpet racking or steel coil racking.

Reach Forklift

Reach forklifts are named for their ability to extend the tynes forward to load or unload a pallet. Built with stabilising legs at the front, reach forklifts are able to reach further into a racking system than a standard forklift to access items up to two pallets deep.

The low ground clearance of a reach forklift makes it only suitable for use indoors on flat surfaces to prevent damage to the undercarriage. Reach forklifts are designed with a more open cab to provide greater visibility when loading and unloading pallets overhead.

With a lift height of up to ten metres, reach forklifts are suitable for use with a range of pallet racking systems, including double deep pallet racking where other forklifts would require a special attachment.

Side Loader Forklift

As the name suggests, unlike standard forklifts, side loader forklifts lift and carry loads alongside the forklift operator rather than in front. This makes side loader forklifts ideally suited to transport long and wide loads such as timber, pipes, steel, and sheet materials. Side loaders also offer increased visibility for the operator as the load is carried to the side for an unobstructed view.

There are different variants of side loader forklifts that are suitable for both indoor and outdoor use, as well as a multi-way variant that can rotate up to 90 degrees for increased manoeuvrability which can be useful when operating in narrow aisles.

Side loader forklifts are ideal for use in warehouses that store long materials such as decking, gyprock, and steel lengths, which is why side loader forklifts are often used with racking systems such as cantilever racking that are specifically designed for the storage of long products. The side load carrying and manoeuvrability of side loader forklifts allow long products to be stored and transported efficiently within narrow aisles, maximising storage capacity.

Very Narrow Aisle Forklift

Very narrow aisle forklifts are designed for indoor use in warehouses with limited aisle space. The carriage and tines of a very narrow aisle forklift have the ability to rotate up to 180 degrees, moving independently of the truck, allowing for goods to be easily loaded, unloaded, and transported between narrow warehouse aisles. This allows rows of racking to be installed closer together than a standard racking system to significantly increase storage capacity.

As the name suggests, very narrow aisle forklifts are best suited for use with narrow aisle racking and very narrow aisle racking systems that otherwise require the use of a stock picker.

Telescopic Handler

A telescopic handler is a type of small forklift that is most often used in the agriculture industry. Its telescopic boom allows the forklift to reach far greater heights than that of a standard forklift truck. Suitable for both on-road and off-road use, telescopic handlers come with a variety of attachments for increased flexibility and functionality.

Stand-Up Rider Forklift

Stand up rider forklifts are ideal for use where the forklift operator will frequently be getting in and out of the forklift. The benefit of a stand up forklift is that it provides greater visibility for the operator than when sitting down and is easily manoeuvrable in tight spaces due to its compact size.

Rough-Terrain Forklift

Rough terrain forklifts are typically used outdoors on construction sites, farms, docks, and other areas with rough or uneven terrain. The characteristic feature of a rough terrain forklift is its inflatable tyres that are used to ensure safe, stable movement across uneven surfaces.

Bult with larger tyres and engines than standard forklifts for increased lifting capacity, rough terrain forklifts are also made with a counterbalance weight at the back of the truck in order to offset heavy loads carried on the front tynes.

Different Types Of Forklift Attachments

Forklift attachments are designed to improve material handling processes for safer and more efficient product handling. While often overlooked, forklift attachments can be used to reduce forklift operating hours, saving you time and money.

Additionally, some materials and racking systems cannot be safely loaded and unloaded without the aid of a forklift attachment. This means that failure to use the appropriate forklift attachment can result in product damage and even worker injury. Some of the most commonly used forklift attachments include:

Fork Extensions

Fork extensions are a straightforward forklift attachment that provides extra reach, allowing standard forklifts to access loads stored deeper in a pallet racking system, as well as to safely transport pallets that are larger than the standard size.

It is important to note that fork extensions must be correctly sized for the intended forklift to prevent the forklift from toppling over when lifting heavier loads.

Side Shifters

Side shifters are a time-saving forklift attachment that allows loads to be shifted from side to side when needed. This allows operators to make small adjustments and line up their load accurately without having to move the entire forklift.

Pole Attachments

A pole attachment is a long spike-style jibs that are used to shift rolls of carpet, vinyl, and similar materials stored in a carpet racking system. Without a forklift pole attachment, carpet rolls will need to be loaded and unloaded from shelving by hand.

Fork Positioners

Fork positioners are an attachment that allows the tynes of the forklift to be moved hydraulically closer together or further apart to accommodate different sized loads. The movable forks also allow operators to align the forklift with the load more easily than when using a forklift with no attachment. The increased flexibility of a forklift using a fork positioner attachment can improve load handling times and increase productivity.

Fork Rotators

Fork rotators allow forklifts to safely rotate the load 360 degrees and are typically used for inverting and pouring load contents and returning the forks to an upright position in a single movement. This type of attachment is typically used in food processing and agricultural industries.

Twin Pallet Handler

A twin pallet handler forklift attachment allows the forklift to lift and transport two pallets at once, side by side. This essentially means that one forklift is able to do the work of two, saving time and money. One factor to consider when using a twin pallet handler is that the load width is significantly greater, making the truck less manoeuvrable in tight spaces.

Choosing The Right Forklift For Your Warehouse Storage System

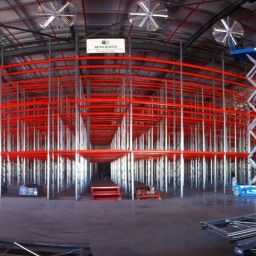

Forklifts are an essential part of most warehouses, allowing for the safe and efficient transport, loading, and unloading of palletised goods as well as various other large and heavy objects. Using forklifts in conjunction with a warehouse pallet racking system is a surefire way to increase storage capacity and productivity in your facility.

Choosing the right type of forklift and forklift attachments for your pallet racking system will not only maximise productivity, but will also ensure that your pallet racking system does not become damaged from inappropriate use, which can result in a pallet racking collapse. When it comes to pallet racking, Macrack are the experts. In fact, we have been manufacturing quality, Australian made pallet racking systems for over 40 Years.

Whether you’re in the planning stages of fitting out a new warehouse or you want to know which type of pallet racking system is compatible with your existing forklifts, Macrack has the answer. Talk to one of our friendly warehouse storage specialists today on 1800 048 821 for expert advice on choosing the right forklift for your pallet racking system.