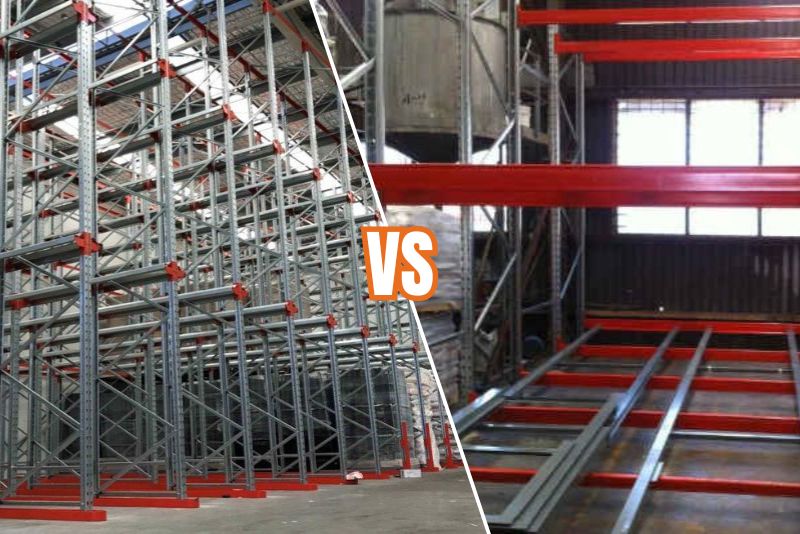

Warehouse efficiency hinges on the right storage system. Among the many options, Drive-In and Push Back Pallet Racking stand out for their ability to maximise space and improve inventory management. At Macrack, we’re a leader in warehouse storage and pallet racking solutions, offering both systems tailored to diverse storage needs. Understanding the distinctions between these systems is key to optimising your warehouse’s operation.

Drive-In Pallet Racking: Maximising Space for Bulk Storage

Drive-In Pallet Racking is engineered for storing large quantities of similar products. This system achieves high storage density by arranging pallets depth-wise in continuous rails, which minimises the footprint and is particularly beneficial in space-constrained areas like cold rooms.

Key Features and Benefits:

- High Density Storage: Maximises both floor and storage space, ideal for bulk storage of identical products.

- Efficiency in Cold Storage: Exceptionally suits chilled and cold storage spaces, ensuring a smaller footprint with high-capacity storage.

- Cost-Effective: Requires fewer accessories and no specialised equipment, making it an economical choice for high-volume storage.

- Product Suitability: Best for fast-moving items or products with a long shelf life and limited stock rotation needs.

Push Back Pallet Racking: Enhancing Selectivity and Efficiency

Push Back Pallet Racking operates on a Last-In, First-Out (LIFO) principle using dynamic carts on rails. Pallets are stored up to six deep and pushed back onto separate carts, providing high-density storage with better selectivity and efficiency than Drive-In systems.

Key Features and Benefits:

- Increased Selectivity: Offers 3 to 5 times more pick faces than Drive-In racking, enhancing picking efficiency without entering storage lanes.

- Optimal Space Utilisation: Achieves up to 90% more product storage than selective racking systems, with up to double the stacking height.

- Versatile Stock Management: Allows for the storage of a variety of SKUs on different levels for easy access.

- Ease of Use: Compatible with standard forklifts, eliminating the need for special equipment.

Making the Right Choice for Your Warehouse

The decision between Drive-In and Push Back Pallet Racking hinges on your specific storage needs:

- For Bulk Storage of Similar Products: Drive-In Pallet Racking is unmatched in its ability to store large quantities efficiently, making it the go-to for warehouses where product variety is minimal and space is at a premium.

- For High Density and Selectivity: Push Back Pallet Racking offers the best of both worlds, providing high-density storage with the added benefit of improved access and selectivity. It’s ideal for operations that handle a variety of products and seek to enhance picking efficiency.

Both systems offer unique advantages, from the high-density, bulk storage capabilities of Drive-In Racking to the improved selectivity and operational efficiency of Push Back Racking. Your choice should align with your warehouse’s operational needs, product types, and space considerations.

For professional guidance on selecting the perfect pallet racking system for your warehouse, or to request a design and quote, contact Macrack pallet racking at 1800 048 821. Our experts are dedicated to delivering storage solutions that optimise space, improve efficiency, and drive your business forward.