Push back pallet racking is a high density storage system that can be used to increase storage capacity and maximise productivity. In a push back racking system, pallets are loaded onto carriages that sit on a pair of rails. The rails are set on an incline towards the front of the system. This means that whenever a pallet is removed, the remaining pallets are automatically rolled forward towards the front of the system.

The automatic shift of pallets from the back of the system to the front allows for easy unloading, as the frontmost pallet will always be in the closest position to the aisle until the entire track is empty.

When Should Push Back Racking Be Used?

Push back pallet racking is ideal for the storage of product ranges with low to moderate product differentiation. The customisable shelf depth of 2 to 6 pallets deep offers the benefits of high density storage. And unlike other high density racking systems, push back racking allows pallets to be picked from each location for improved product selectivity.

The Benefits Of Drive Pallet Racking

Maximise Productivity

The moving carriages onto which pallets are loaded and unloaded in a push back pallet racking system allows the force of gravity to automatically push forward the remaining pallets as each pallet is removed.

This maximises productivity as pallets are automatically rolled towards the front of the system each time a pallet is removed, making it just as easy to unload the first pallet as it is to unload the sixth pallet in each row.

Increase Storage Capacity

One of the greatest advantages of a push back pallet racking system is increased storage capacity. As a push back racking systems can be designed to store between 2 to 6 pallets in each location, this system can store up to 90% more pallets than a standard pallet racking system with the same number of aisles.

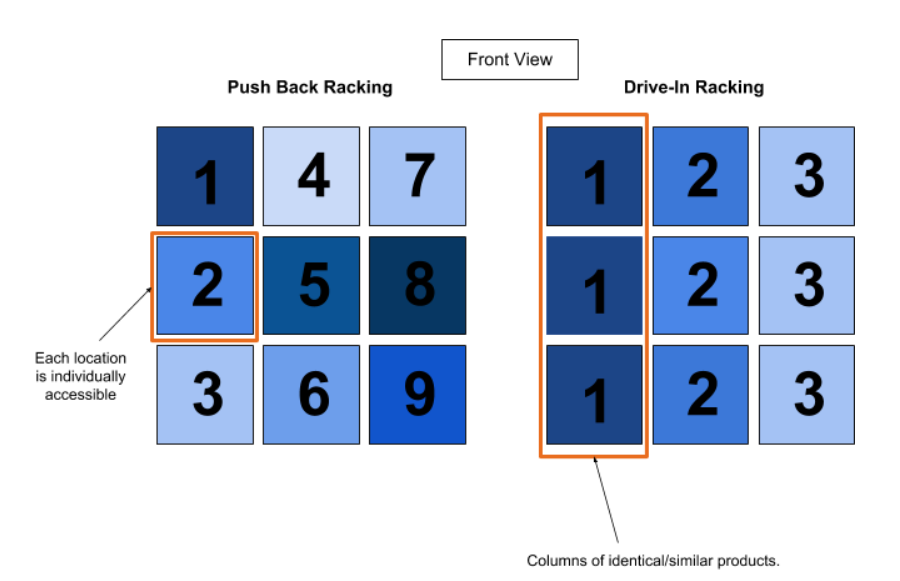

Product Selectivity

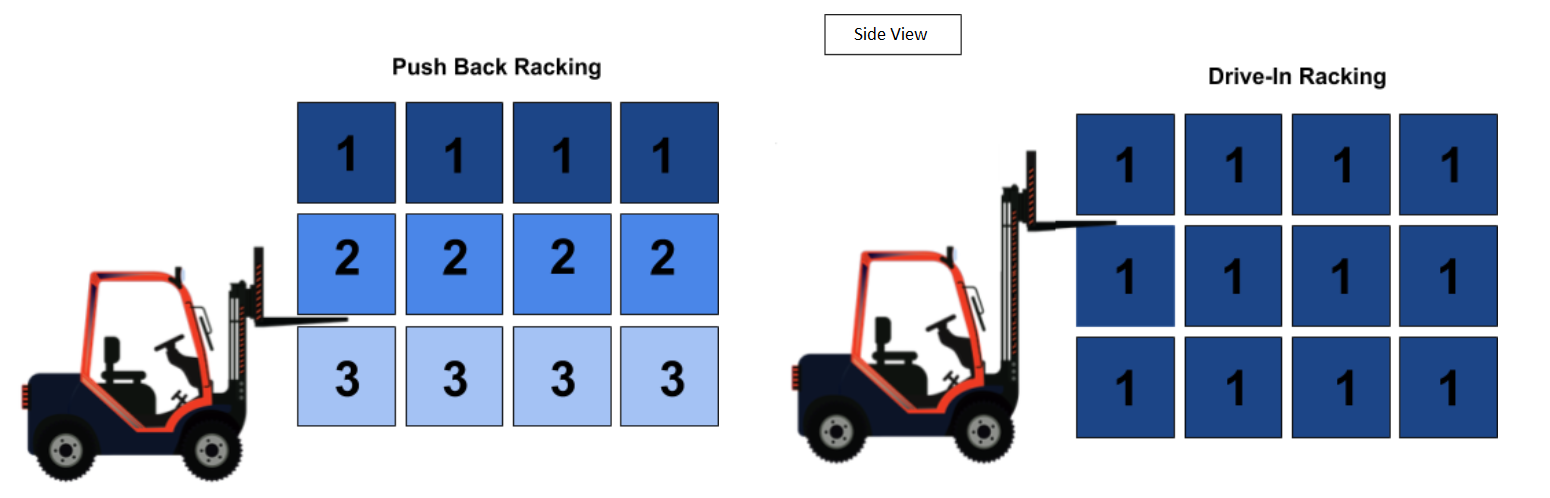

Push back pallet racking offers greater product selectivity than comparable drive in racking systems. This is because, in a push back pallet racking system, pallets are automatically rotated towards the front of the system whenever a pallet is removed. This means that unlike in a drive in pallet racking system, pallets can be independently loaded and unloaded from every level of the system.

Because of the increased product selectivity of a push back racking system, push back racking can be used to store product ranges with a greater number of SKUs than other high density systems of a comparable size.

Highly Customisable

Another benefit of push back pallet racking is that it can be custom made to suit your product range. Not only can a push back racking system be customised to be anywhere from 2 to 6 pallets deep, we can also customise the number of rows and number of levels in the racking system.

Whether your warehouse has ample floor space with a low ceiling or high ceilings with limited floor space, MACRACK can create the ideal push back pallet racking system to maximise the storage capacity of your space.

Forklift Compatibility

The inclined rail and moving carriage system of a push back pallet racking system means that unlike other high density racking systems, push back racking is compatible with standard forklifts. This is because pallets are automatically rolled towards the front of the system as each pallet is removed, negating the need for specialised forklifts or forklift attachments with extra reach.

This means that you can increase the storage capacity of your warehouse with a push back racking system without having to also invest in new stock handling equipment.

Considerations Of Push Back Pallet Racking

Pallet Accessibility

One consideration of push back racking is pallet accessibility. As multiple pallets are stored in each location, and can only be loaded and unloaded from the front of the system, push back racking is a LIFO (last in, first out) system. This means that the last pallet loaded into each location will be the first pallet that is unloaded.

This should be taken into consideration if your warehouse stores products with a limited shelf life or high product differentiation.

If you’re looking for a high density, FIFO (first in, first out) storage system, click here for more information on our pallet flow racking system with automated stock rotation.

If you’re looking for quality, Australian-made push back pallet racking with a lifetime guarantee, MACRACK has the solution. Or if you’re not sure which racking system is best for your warehouse, call us today on 1800 048 821 to speak to one of our racking specialists.

Contact The Team at Macrack Today

We’re The Experts in Industrial Racking and Storage Solutions