Garage Door Storage at Stoddart Group

-

- Odd sized product – Check!

-

- Innovative storage solutions – Check!

- Building a lasting relationship – Check!

Macrack and The Stoddarts Group have worked together to form innovative ways to store the vast amounts of products that they have warehoused Australia wide. This has formed a solid relationship between Stoddarts and Macrack enabling development of product and creating a safe work environment by having racking that suits their needs.

Leaders in the supply and installation of steel roofing, fascia, gutter, patios, downpipes, solar systems, steel house frames and commercial safety systems.

OH&S

Originally stoddarts would unload a shipment of garage doors directly off the truck onto the ground. As the garage doors don’t come on pallets, they had to do this by hand. This required two men, one on either end of the door, to manually move the product around. After the doors have been assigned to a job, they are bundled together with other items and continued to sit on the ground until the installers picked them up for that days job.

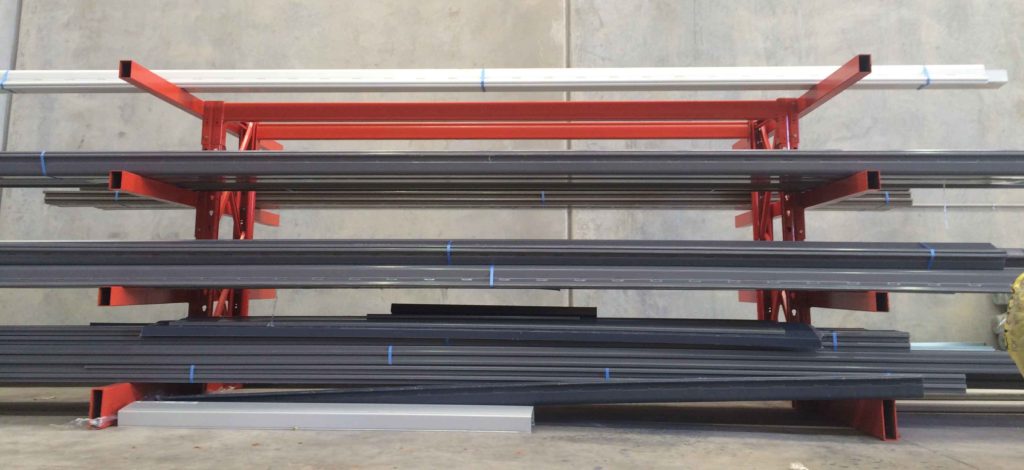

Due to safety concerns from manually lifting heavy garage doors, Stoddarts decided to implement a racking system where they would utilise racking to prevent repetitive lifting from ground level. They took on board all work flows procedures, and considering that the product was odd in size, 5m long but light enough to manually lift, they were now to be stored in hand picking cantilever rack. This helped removed the danger of fatigue and increased storage capacity.

Racking Development

From originally storing product on the ground, Macrack worked with Stoddarts to create a solution to both increase warehouse storage capacity and allow for a safer work environment. Creating low profile cantilever racks, numerous doors could be stacked and readily accessed when a job needed to go out. It also prevented the need to constantly bend over to pick up the product, as all doors were at knee to shoulder height.

As the company grew, they soon realised that they needed more storage per warehouse and the only way to do it was to go up. Working with their warehouse managers we devised single and double sided cantilever system that allows them to store 9 packs of doors per bay. This dramatically increased their storage capacity, but also meant that they needed to operate with forklifts, removing the manual handling component of the work flow.

Warehouse Storage Solutions

Double Garage doors Rack

Product description : 5meters in length x 300mm high x 600mm deep. Approx. 50Kg

Method of storage : Cantilever racking with light duty arms and a wide bay width.

Reasoning : Product that size and length is perfect for cantilever racking.

Guttering Rack

Product description : 1200mm – 6500mm long. 500grams per meter.

Method of storage : Long Span Shelving with board (to hold short lengths). Reverse stub arms to hold long pieces

Reasoning : Gutters could come in at any length, so it was hard to have set distances. However full lengths needed to be stored safely as well, so stub arms that acted as a mini cantilever were utilised to full potential.

Single Garage doors Rack

Product description : 3.5meters in length x 300mm high x 600mm deep. Approx. 30Kg

Method of storage : Selective pallet racking with fork entry bars.

Reasoning : Storing the smaller product this saved money compared to the cantilever version, because we could utilise standard size beams.

Screws and hardware

Product description : Boxes of steel roofing screws, 5kg each.

Method of storage : Heavy duty Shelving

Reasoning : These boxes were to be handpicked in daily operations, but needed a strong solution to store that weight. So shelving with board supports allowed them to achieve the weight loads.