Dynamic Cart On Rail Pallet Storage

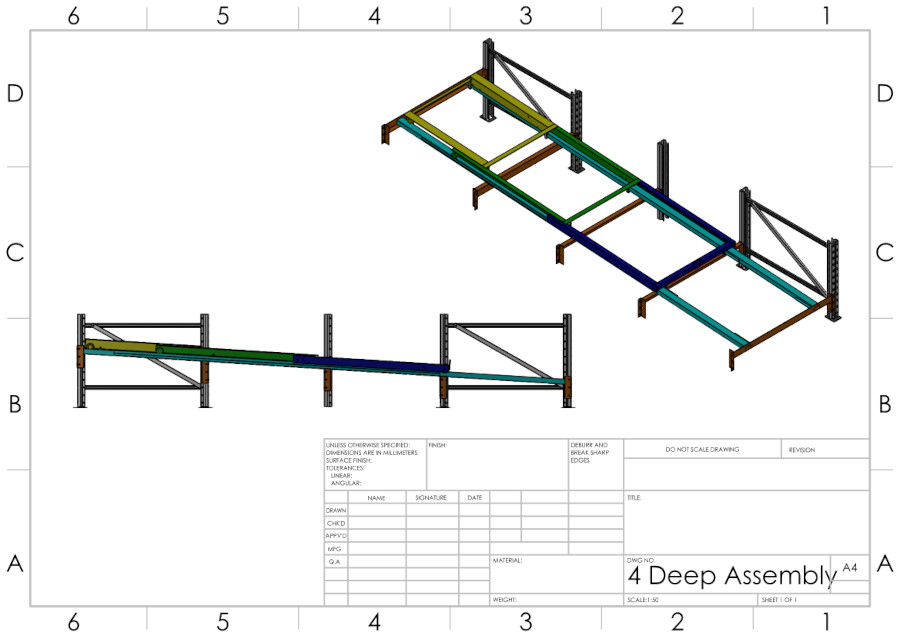

Push Back Rack is a Last-In First-Out (LIFO) dynamic cart on rail pallet storage system. It comprises a number of storage lanes, up to 6 pallets deep, where pallets are located on carts with each successive pallet ‘pushed back’ on a separate cart along on a pair of structural steel rails supported within a rack framework. Storage lanes are installed at a gradient allowing the rear pallets to travel forwarded by the force of gravity.

Our Brisbane manufactured Push back racking is ideal for the storage of multiple pallets of the same product as only the front pallet of each location is accessible from the aisle. However, this type of racking allows for a much higher differentiation in products than comparable drive in racking systems. This is because each track is independently loaded and unloaded allowing for different products to be stored in each location, both horizontally and vertically.

BENEFITS

- Offers the same high density pallet storage as Drive In Pallet Racking, however, offers greater selectivity; 3 to 5 times the number of pick faces

- Increased picking efficiency over Drive In racking. Pallets are all picked or placed from the main aisle without having to drive into storage lanes

- Better use of warehouse space – Push back offers up to 90% more product storage than selective racking systems

- High density storage with increased picking productivity

- Store a variety of stock keeping units on different levels of lanes for easy product access

- Interlocking cart assists which prevent blocking , jamming and costly product damage

- Maximizes space utilization

- “Last in, first out” inventory

- 50% saving in aisle width

- Achieves up to double the stacking height normally obtained from alternative storage systems

- Do not require a special forklift to operate. Any forklift will work.

Material Handling Equipment: Forklift with standard tynes

Hand-picking: No

Ideal for: Great for bulk storage of the same product on pallets

As a racking manufacturer our systems are often made to order to best suit your business needs. All our products are ‘price on application’ (POA). But don’t despair, we are willing to give you a price over the phone. No job too big or small. Whether you are looking for industrial sheet racking units for sale or a full warehouse racking design and quote call the team on 1800 048 821.

Contact Macrack Today

Ask our team for a free design and quote

What Is Push Back Pallet Racking?

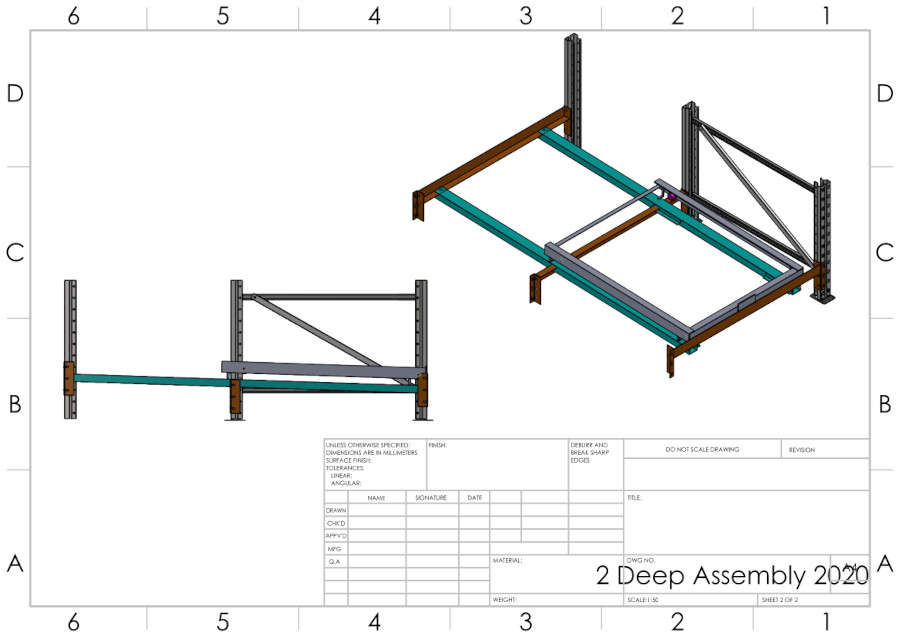

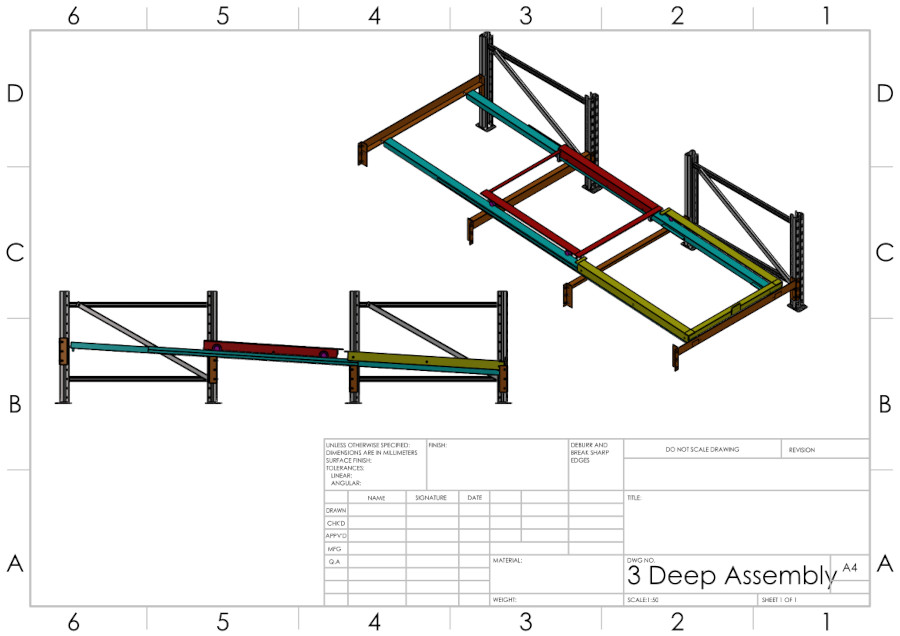

Push back racking is a pallet racking system that can be anywhere from 2 to 6 pallets deep. Push back racking uses a moving cart system where pallets sit on carriages. Pallets are loaded and removed from the front of the system relying on the force of gravity to roll the remaining pallets forward each time the front pallet is removed.

This makes stored products easily accessible as the pallets will always move to the front of the system until the entire track is empty.

Our Brisbane manufactured Push back racking is ideal for the storage of multiple pallets of the same product as only the front pallet of each location is accessible from the aisle. However, this type of racking allows for a much higher differentiation in products than comparable drive in racking systems. This is because each track is independently loaded and unloaded allowing for different products to be stored in each location, both horizontally and vertically.

Push back pallet racking is a last in, first out (LIFO) system meaning that it is not suitable for the storage of perishable products.

How Push Back Racking Works

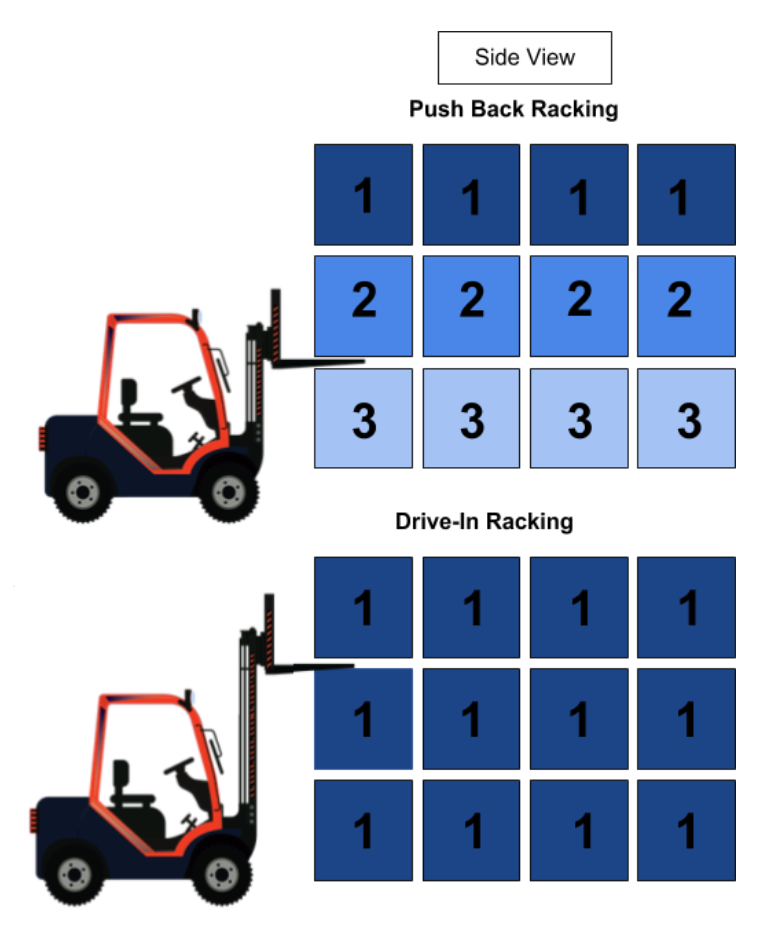

A pushback rack system contains a pair of inclined rails and a series of nesting carts which ride on these rails. The first pallet is loaded on the top cart by a forklift. When the operator comes in with the second pallet, they push the first pallet back and rests the second pallet on the middle cart. Similarly, the 3rd pallet pushes back the first 2 and rests on the bottom cart. The operator loads the last pallet by pushing back the first 3 and placing the load on the pair of rails. When unloading the pushback rack, the sequence is reversed. The rails are inclined toward the aisle, so when the operator picks up the pallet resting on the rails and backs out, the 3 remaining pallets will follow to the front of the lane. They can then remove each pallet in succession, until the lane is empty.

The Benefits Of Push Back Pallet Racking

Improve Warehouse Processes

Push back pallet racking is designed so that each time a pallet is removed, the pallets behind it automatically slide to the front of the racking system. This makes it easier for the forklift operator to remove the next pallet without the need for forklift attachments or having to switch to the specialised equipment that is required for similar high density systems, such as double deep racking.

This also makes push back racking faster to load and unload than drive in racking as each pallet is loaded from the front and automatically moves forward as pallets are unloaded.

Increase Storage Capacity

Push back pallet racking can be used to increase storage capacity in a warehouse without increasing the number of aisles. This is because push back racking can be up to six pallets deep per system. Additionally, racks can be placed back to back to store a maximum of ten pallets between aisles.

This means that a push back racking system can increase storage capacity by up to 60% when compared with a double deep racking system configuration with the same number of aisles.

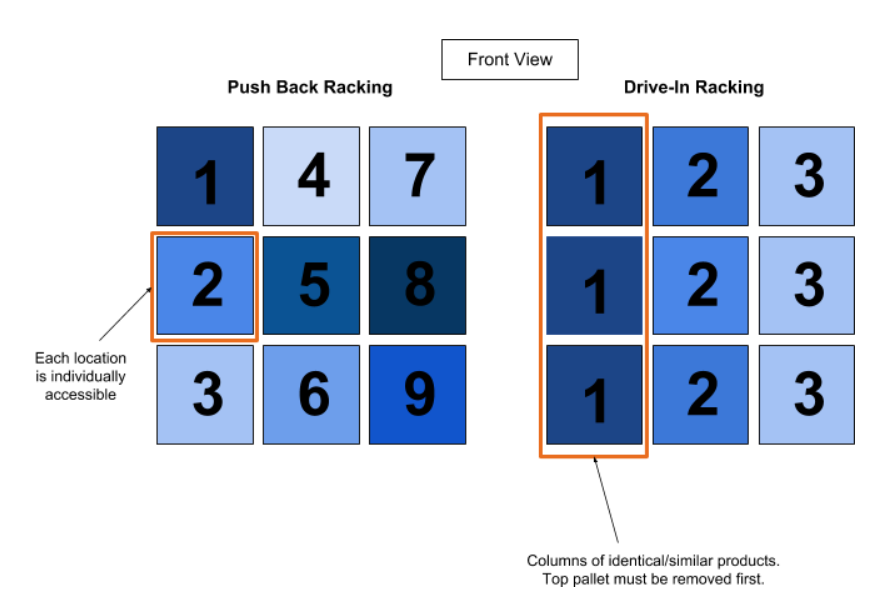

High Density – Moderate Product Differentiation

Push back pallet racking is a high density pallet racking system that can be used for product ranges of low to moderate differentiation. In a multi-level push back racking system, each track is individually accessible allowing for the storage of different products in each location. This gives push back racking a higher accessibility than comparable high density systems such as drive in racking. This is because a drive in racking system requires pallets to be removed in order from top to bottom meaning identical or similar pallets must be stored in columns. (See image 1 below).

For example, in a push back racking system that is three pallets high, four pallets deep and three pallets wide, nine pallets are immediately accessible from the front of the aisle which means you can store nine product types in the system without reducing accessibility.

Conversely, in a drive in racking system, you must remove the pallet at the top of the stack to access the pallets below. So in a drive-in system of the same configuration, only three pallets are immediately accessible from the front of aisle meaning that you can store a maximum of only three product types without affecting product accessibility. (See images 1 and 2 below).

Compatible With a Standard Forklift

Another benefit of push back racking is that, unlike other high density storage systems, it does not require a specialised forklift with extra reach. This is because the inclined rails of a push back racking system means that each time a pallet is removed, the next pallet slides forward into the front position which is accessible by a standard forklift.

This means that push back racking affords you the benefits of a high density storage systems without requiring a new specialised forklift or long reach attachment, saving you money.

Push Back Racking Customised to Meet Your Needs

The carriages on a push back racking system can be 2-6 pallets deep, and you can have as many across as you like. You can also request your system to incorporate multiple levels. No matter how high, wide or deep your ideal racking system would be, we can tailor the perfect solution for you.

At its core, this is a system designed for warehouses with a large amount of similar product. The most effective and logical way to benefit from push back racking is to store identical or similar items in each carriage system/location. This simplifies stock locations, preventing products from getting mixed up or lost.

If you need LIFO racking call MACRACK on 1800 048 821 for a chat. We can run through the pros and cons of each system and work with you to decide what would suit you and your warehouse best. We might even help you realise that the perfect storage solution for your business is one you’ve never thought of! Contact us today to get started.

Get A Free Design And Quote

Ensure Your Warehouse Storage Solution Has A Lifetime Guarantee Call Us Today

Our Clients

Providing Quality Racking At Great Prices For Over 40 Years

“Customer service is exceptional. The staff are very friendly and helpful when I had any questions and queries. They provided me with all the information I needed and some that I didn’t even know I needed. When I organized something with them, they did exactly what they said they would do and they were always polite and punctual. The price is very competitive and I would recommend Macrack to anyone needing Racking Solutions.”

Paul C – Google Review

“Macrack Australia have been a pleasure to deal with on both occasions we have now used them. From the advice and suggestions given to maximise our space and storage, through to the team at install, we have had a very good experience and would highly recommend Macrack for your warehouse and storage needs. A+ Thanks Gary and the team.”

Mick A – Google Review

“I would like to take this opportunity to thank the team at Macrack for the quality of work and product they supply. The staff are wonderful and it is great to see such professionalism thru-out this company.

Jeff is a real asset to the business and it is always a pleasure to deal with the ladies in admin (Jo).”

Willie M – Google Review

“We have tried other brands of rackings, but hands down the product from Macrack is by far the better choice. Rackings are designed to test the extreme elements and most importantly high standard of customer service. Highly recommended!”

Victor S – Google Review

“I highly recommend Macrack to any business looking to install pallet racking or stock shelving. From designer Leo through to the professional staff who replaced all the shelving in our warehouse and installed new pallet racking. The co-ordination was great and they fitted in with our tight schedule. Any query was answered promptly. Pricing was very competitive as well.”

Brian D – Google Review

Get A Free Design And Quote

Ensure Your Warehouse Storage Solution Has A Lifetime Guarantee Call Us Today

Send us a message and our team will get straight back to you with a price. Looking for a complete warehouse design to optimise space and efficiency? Take advantage of our experience with a free warehouse design service.

View Our Product Range

Contact Us

Phone: 1800 048 821

HQ Phone: 07 3343 9788

Email: [email protected]

Address: 40-42 Devlan St, Mansfield, Brisbane QLD 4122

Mail: PO BOX 50, Pinkenba QLD 4008

Despatch: 22 Devlan Street, Mansfield, Brisbane QLD 4122.