With a well-planned design based on the needs of your warehouse, line marking can be used to improve three of the most important aspects of any warehouse: organisation, efficiency, and safety.

The combination of workers on foot, site visitors, material handling equipment and vehicles all in one place makes any warehouse a hazardous environment. Professional line marking provides clear visual cues to anyone who enters the warehouse, whether as a pedestrian or while operating heavy machinery, to reduce the risk of accidents, injuries, and collisions.

Why Should You Line Mark A Warehouse?

There are three main benefits to line marking a warehouse: increased safety, improved organisation, and maximised efficiency.

Increase Safety

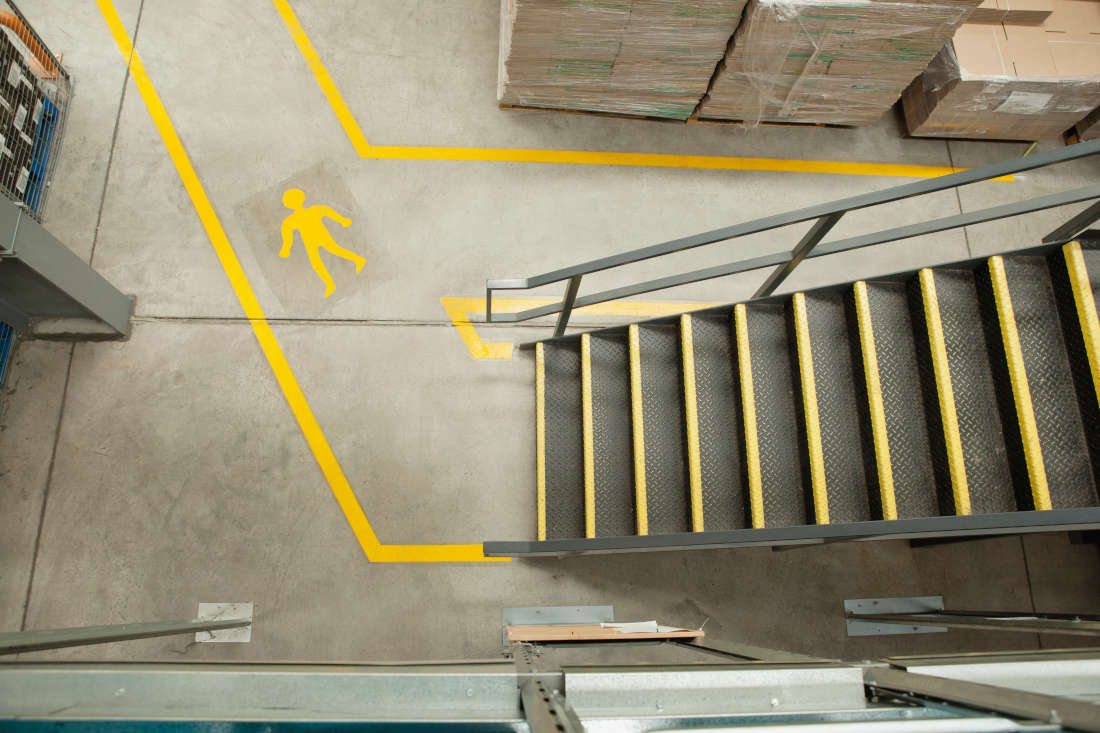

One of the most obvious benefits of line marking a warehouse is increased safety. With line marking you will be able to clearly mark out different areas and their intended purposes, such as designated walkways and areas where heavy machinery will be operating. This will give equipment operators a visual cue to prevent them from entering designated walkways, reducing the risk of collisions and injuries.

By the same token, line markings will indicate to pedestrians when they are entering an area where vehicles operate or other hazardous areas, allowing them to proceed with extra caution and vigilance to prevent an accident.

Improve Organisation

Line marking can also be used to improve the organisation of a warehouse by clearly marking out different areas, such as areas designated for the disposal of hazardous waste. Additionally, creating an organised arrangement using line markings can ensure that all products and equipment are stored in the right locations, making it easier to locate items within the warehouse.

This will also ensure that walkways are kept clear to keep your warehouse safe and tidy by providing a border past which pallets, boxes, and other objects should not extend beyond.

Maximise Efficiency

A well-planned layout that is clearly marked through the use of line markings can increase efficiency by reducing the amount of time spent navigating different aisles and areas. Line markings can also be used to arrange products in the optimal layout based on your warehouse processes to reduce manual handling and increase productivity.

Line marking can also be used to maximise efficiency in a warehouse by streamlining the movement of both workers and vehicles by keeping them in their designated areas. Conversely, an unmarked warehouse floor can result in unnecessary traffic jams and disruptions as a result of multiple workers and machines vying for the use of the same pathways.

What Areas Should You Mark?

There are many different applications for line marking in a warehouse, from creating a border and additional layer of safety around large pallet racking systems to marking out hazardous areas.

Floor Layouts

Line marking provides a simple way to keep your product storage organised and facilitates the accurate tracking of goods in and out of the warehouse by marking out designated storage areas as well as walkways and vehicle traffic pathways.

Hazardous Areas

In a warehouse environment, there are many hazardous areas that everyone should be aware of, whether they are a warehouse worker or a site visitor. Line markings provide an easy way to do just that, giving a clear indication that you are entering a hazardous area, such as a heavy traffic area or an area that is designated for the disposal of hazardous waste.

Pedestrian Walkways

Marking out pedestrian walkways will allow workers and visitors to safely navigate the warehouse on foot while signalling to vehicle operators not to enter.

Pallet Racking Edges

Pallet racking is the backbone of any warehouse, providing an organised way to store products and making use of vertical space to maximise storage capacity. A pallet racking collision is one of the most serious incidents that can occur in a warehouse environment as a racking collapse is likely to damage your material handling equipment, product storage system, and stored products and cause serious or even fatal worker injuries.

Pallet racking edge line marking not only gives forklift operators a clear line to ensure pallets are kept behind in order to leave aisles free from obstruction with clear access to the upper levels of the racking system, but it also provides a stand-out visual indicator to vehicle operators that they are getting close to the racking system and that they are at an increased risk of colliding with the racking system. Informed by the line markings, workers operating near the racking system are able to proceed with extra caution to reduce the risk of an accident.

Do The Colours Matter?

The colour of your line markings should correspond to what you intend the lines to indicate. For example, yellow lines are typically used to indicate aisles, walkways, and pallet racking edges. Red lines indicate high-risk or hazardous areas, and a striped red and white line indicates restricted access areas.

Line Marking In Australian Warehouses

The professional planning and line marking of your warehouse can significantly reduce safety risks, including collisions and worker injuries while improving organisation and navigation for increased efficiency.