What is Drive In Pallet Racking?

Is it time to use drive in racking to increase your warehouse storage?

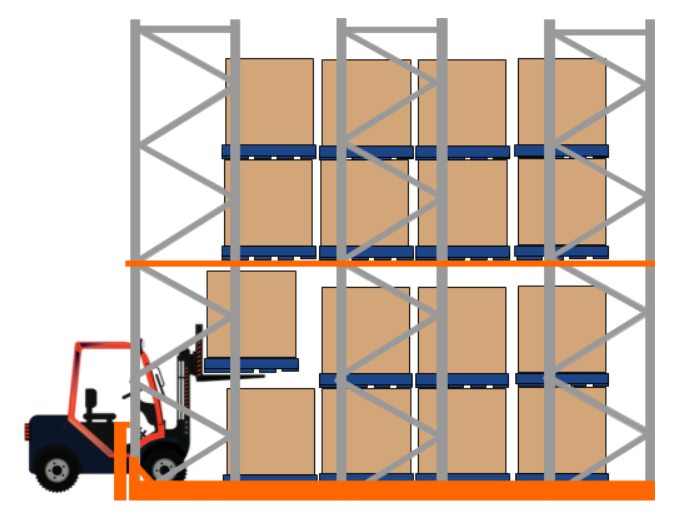

Drive in pallet racking is a high density pallet racking system storing up to 75% more than the standard selective pallet racking system due to the fact that there are no aisles. Drive in racking uses runners rather than beams allowing forklifts to drive between the uprights and into the pallet racking system, from one side, to load or unload pallets from the system. Drive in pallet racking is a highly customisable racking system with the ability to adjust height, width and depth to fit specific requirements.

A single entry point drive in pallet racking system is a form of LIFO (last in, first out) storage making it suitable for the storage of large quantities of the same or similar products. However, there is also the option of a double entry configuration where pallets in the racking system can be accessed from either side.

This is called back to back drive in, where you have a number of pallet locations that are accessible from either side, so you can help separate your product lines without increasing the amount of space that is used. However, if you want a system that allows for pallets to be placed in one end and despatched from the other, you are looking for FIFO racking, which is also called Pallet Flow.

When Should Drive In Racking Be Used?

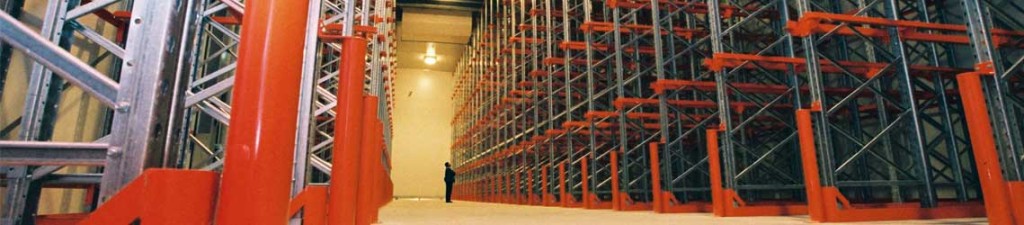

Drive in pallet racking is ideally suited to store bulk amounts of the same or similar products. It is also very well suited for cold room and freezer storage or any other type of storage where the cost per square metre is high. This is because drive in pallet racking negates the need for aisles meaning that all of the expensive floor space in your temperature controlled storage room is being optimised for product storage.

Benefits of Drive In Racking

High Density Storage

A huge benefit of using a drive in pallet racking system is the extra storage capacity. Drive in pallet racking is a high density racking system that can be custom built for your space to maximise storage capacity. Plus, forklifts can drive into the system to load and unload pallets, eliminating the need for aisles. This means that you can store a lot more pallets in a drive in racking system than a selective pallet racking system of the same size.

Suitable For Unconventional Areas

Drive in pallet racking allows you to utilise every space in your warehouse. Whether you have a confined area where a pallet racking system with aisles would not be able to fit or a long empty corridor where a standard racking system would not be suitable. Drive in racking requires front access to only one side of the system and can be used to maximise the storage capacity of a previously unusable space.

Product Protection

Another benefit of drive in pallet racking is additional product protection. As only a fraction of the pallets are accessible from the front of the system, the remaining pallets are stored behind them. This provides extra protection for the pallets in the system as they are not exposed to potential damage caused by general warehouse operations such as forklift collisions.

Additionally, drive in pallet racking can be used to store fragile products that cannot be stacked while maintaining the high density storage of stacked pallets. This is because, in a drive in racking system, the runners take the load of each pallet preventing the weight of higher pallets from damaging products in the pallets below.

Highly Customisable

Another benefit of pallet racking is that it can be designed and customised to suit any space or warehouse operations. Unlike most other racking systems, drive in pallet racking can be customised three ways; length, depth, and number of levels. This means that you can have floor to ceiling storage at whatever depth you need whether you have a narrow floor space with a high roof or a large floor space with a low roof.

Drive in pallet racking can also be configured to have a single entry point or back to back entry points to suit your warehouse operations.

Double Entry Configuration

Not only can drive in racking provide high density storage with a single access point, it can also be configured to have back to back entry points where you can access the rack from both sides, as well as drive in from both sides. This is particularly useful for delivery and despatch storage where you can store products in ‘daily runs’ or ‘intake’ for a clean and organised operating system.

Compatible With Standard Forklift

A pallet racking system is a sizeable investment for business owners so the last thing you need after purchasing a whole new racking system is to find out that you also need to buy new forklifts and stock picking equipment that is compatible with the system.

Unlike other high density storage systems, drive in pallet racking is suitable to most standard forklifts. This is due to the fact that the forklift can drive into the system to retrieve pallets as if they were at the front of a racking system, whereas other high density racking requires forklifts with extra reach to retrieve pallets deeper in the system.

Drawbacks of Drive In Racking

Higher Risk of Damage

One consideration of drive in racking is that the entry points are highly exposed to the forklift movement. This is due to the fact that each time a pallet is loaded or unloaded the forklift has to drive through the uprights and into the system. We at MACRACK offer a robust system to help prevent any damage to the racking system.

There are also many pallet racking protection products specifically designed to reduce forklift damage to drive in systems such as drive in floor channels. The rounded bollard at the front of the drive in floor channel helps to guide the forklift into the bay and absorb any damage from a forklift collision that would otherwise damage the upright. The floor channel that runs along the entire length of each bay prevents the forklift from catching on the frame and keeps it straight.

Reduced Accessibility

Another drawback of drive in racking is the pallet accessibility. In a drive in racking system, only the pallets at the front are easily accessible leaving the majority of the pallets less readily accessible. However, despite reduced accessibility, drive in racking is still highly efficient for food storage as each product can be stored in its own lane, ready for despatch.

Similarly, the reduced accessibility of a drive in racking system can be worked around with a double entry point configuration where pallets can be accessed from the front and back of the system.

Not sure if drive in racking is right for you? Get on the phone with one of our pallet racking experts. We can even come out to your site to measure your warehouse for free and create a plan layout that will help you visualise how the racking system will work in your space.

Need quality drive in pallet racking Brisbane? Call MACRACK on 1800 048 821. We can design and build a drive in racking system perfectly suited to your space restrictions and warehouse operations.